The willpower energy® BioReactor Prototype & Technology Demonstrator

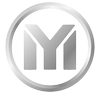

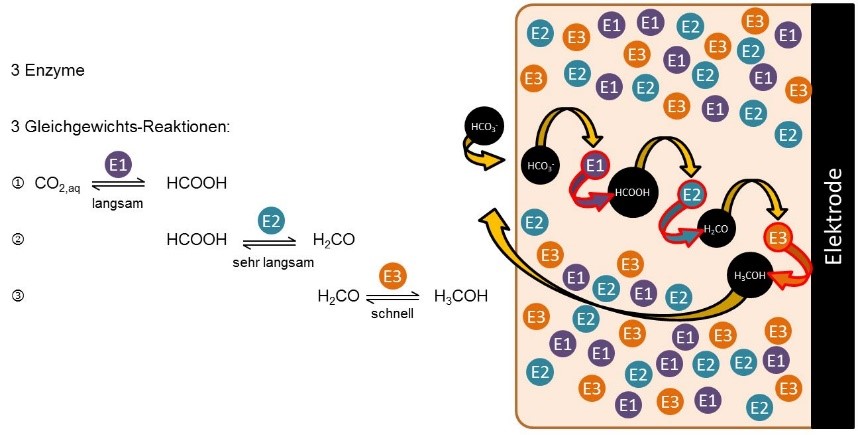

METHANOLOGY's scientific approach is called: "Electrochemical Reduction of Carbon Dioxide to Methanol by Direct Injection of Electrons into Immobilized Enzymes on a Modified Electrode". The technological innovation is the enzymatic reduction to e-methanol without the need of additional co-factors like NADH. We use renewable electricity as the electron donators to the enzymes. This makes it possible to run the process at moderate temperature and pressure conditions, which is more safe and also reduces complexity and cost. We don't use hydrogen gas for the entire process. The catalytic process leads directly into the liquids and oxygen.

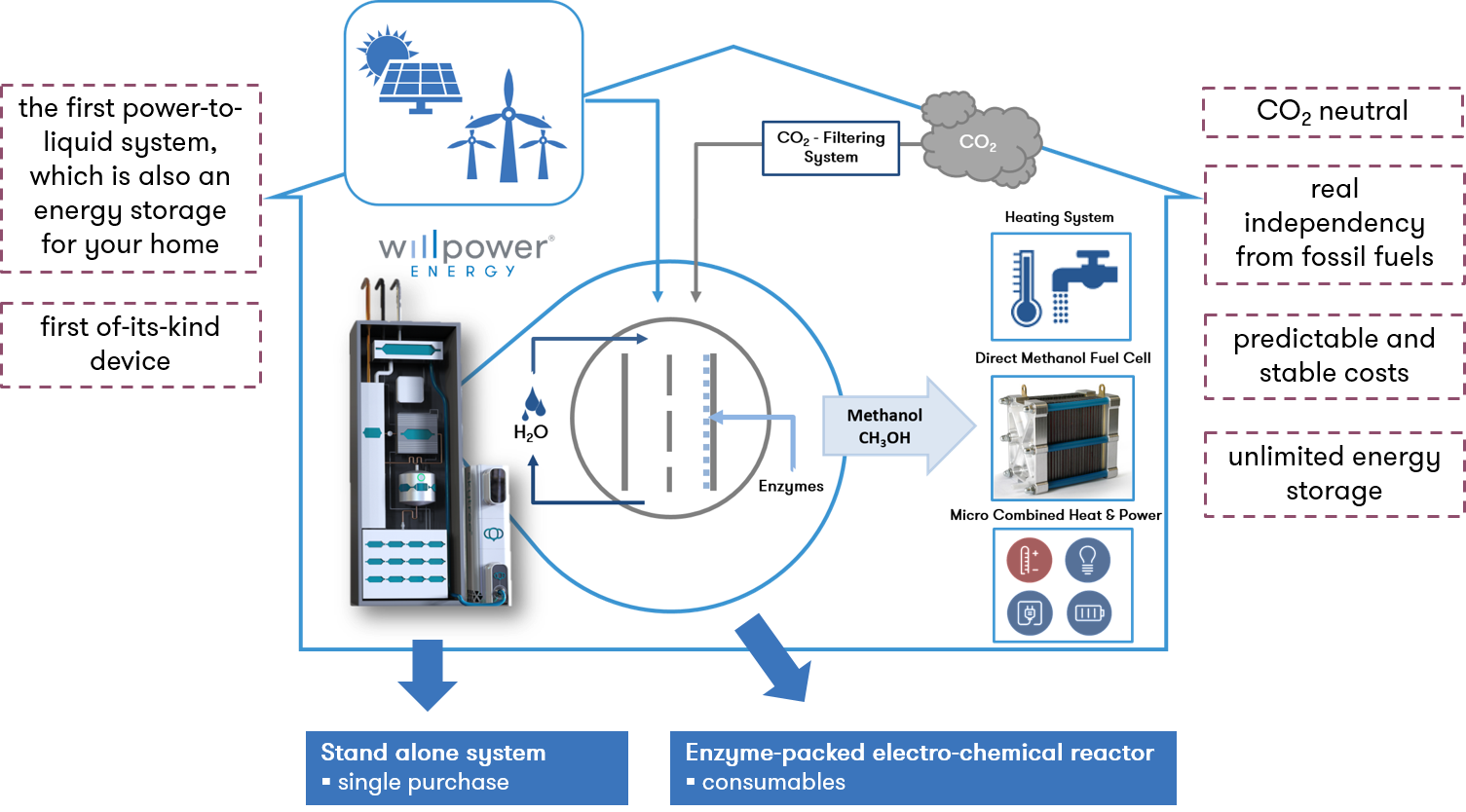

The so called willpower energy® (WPE) bioreactor prototype was installed at a field-test in Germany for more than six months, operated by Gensoric GmbH, a former spin-off company from the University of Rostock and the inventor of the WPE base technology. Let's have a look at the short clip and learn more about this innovative technology:

The field test has confirmed the laboratory results and the technological concept of the electrochemical reduction of CO2 to methanol by direct injection of electrons into enzymes. The first WPE prototype, based on non-improved enzymes on a combined electrode, produced it's e-methanol with an efficiency of 15%, which was a big milestone for the 1st prototype.

At the beginning of 2020, METHANOLOGY took over all rights and patents including the 1st prototype and set up its own engineering laboratory in Neuhausen am Rheinfall (Switzerland) with the aim of implementing the willpower energy® base technology into a market-ready power-to-liquid (PtL) energy storage and e-fuel production system.

The high potential for improvement by evolving the enzyme types and optimizing the reactor and system design can increase the PtL-efficiency of the overall system up to 80% - this is our engineering target.

Illustration of the patented, electro-chemical driven 3-phase dehydrogenase cascade inside the willpower energy® biocatalytic reactor

If you want to dive deeper into the fundamentals of this bio-catalytical process without requiring any sacrificial mediator or electron donor such as NADH, you may check out the following paper: "Electrochemical Reduction of Carbon Dioxide to Methanol by Direct Injection of Electrons into Immobilized Enzymes on a Modified Electrode"

- Why storing energy?

-

Energy storage decouples the time of energy generation from the time of consumption. This means that electricity or heat can be generated and consumed independently of the electricity grid. Well-known energy storage systems are car batteries, mobile phone batteries or night storage heaters, their storage time-frame is limited due to the limited capacity and self-discharge characteristics.

Without effective and long time-frame energy storage based on liquid chemical storage like methanol, a sensible energy transition cannot be implemented, as renewable energies (sun/wind) are not available continuously and in line with demand. Thus, in times of overproduction, what is needed at night or in winter time can be stored in advance (example PV system).

- Why Methanol?

-

Methanol is already the world's second most traded liquid after crude oil. A wide range of industrial applications and products are based on this inedible alcohol, and in some parts of the world (particularly in shipping) it seems to be gaining popularity as the fuel of the future.

Methanol is the ideal hydrogen carrier because it not only has three times the energy density (compared to hydrogen at 700 bar), but it can also be stored and transported in a cost- and resource-efficient way within the existing infrastructure. In addition, environmental risks are minimised as methanol dissolves in water and is broken down by micro-organisms in the event of a leak.

- Why enzymes?

-

Enzymes make the catalytic process incredibly efficient and safe. Because these molecules are highly selective by nature, only the work (in our case a reduction) that is needed is done. In addition, the process can operate at low temperatures and pressures (below 45°C, below 10 bar). This not only saves energy, but also allows use and storage in safety critical areas such as individual homes and urban areas.

- Does it work in the real world?

-

In 2018, a pilot plant at Lake Baldeney near Essen successfully demonstrated how the willpower energy™ solution produces e-methanol from solar energy, water and captured CO2 using enzymes. This liquid stored energy (PtL) was used to power a small excursion boat on the lake, powered by a fuel cell.

The demonstration was a resounding success. The task of METHANLOGY AG is now to further develop the proven concept into a market-ready product that meets all criteria in terms of efficiency, safety and producibility in large quantities fulfilled.